XHE Electronic Handle Applicator Prototype – Horizontal Application of Handles on Cardboard Boxes

Requests to apply handles at low production speeds are rare, but present the same design challenges as those at high speed.

The request is characterized by demanding constraints:

- Application of the handle within precise measurements and positions, with minimal tolerance and high repeatability

- If an application error occurs, the machine must not dent or break the box

- Horizontal application

- Precise and repeatable positioning of the black mark on the handle

- Excellent adhesion along the entire length of the adhesive tape on the cardboard box, ensuring a secure hold and preventing the handle from detaching during transport.

Logical constraints, but quite demanding from a design perspective.

A perfect handle for a special product.

The Prototype

After several meetings with our engineers and technicians, the project led to the solution shown in the following video.

Description of the XHE Handle Applicator Prototype

We sought a solution that is both user-friendly and effective.

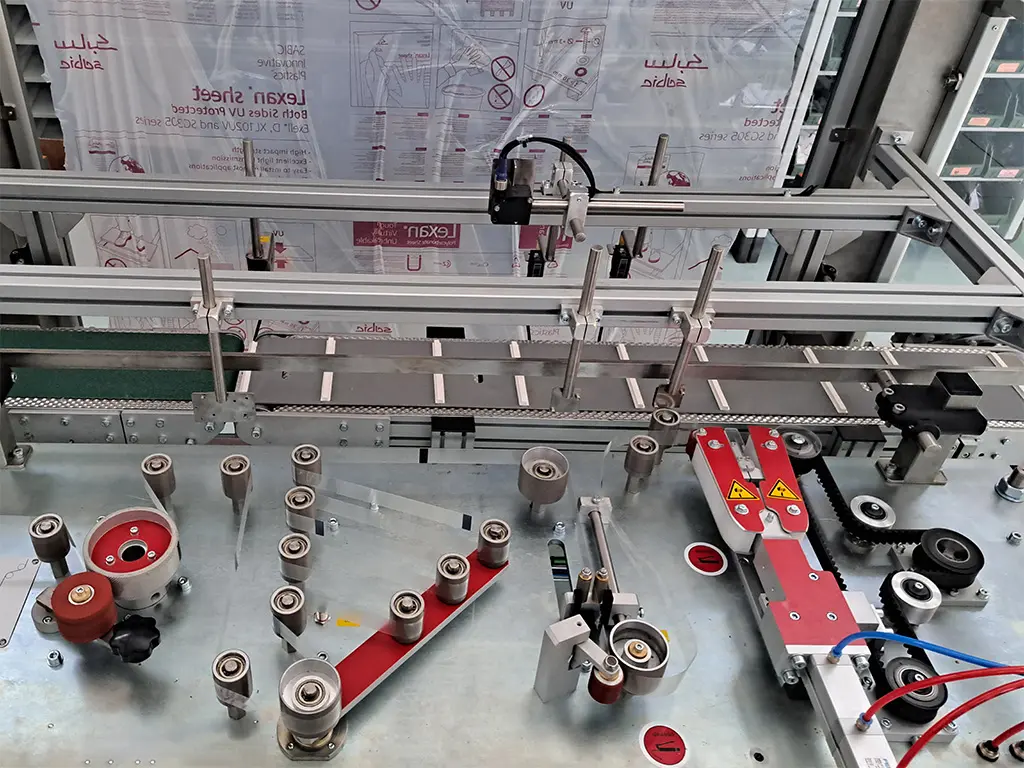

The machine feeds one box at a time via a measuring belt to avoid accumulations and variations due to differing box weights (boxes may contain different products).

Each box is transferred individually to the handling belt by a transfer belt.

Given the low speeds, we opted for intermittent movement and handle application with the box stationary to maximize adhesive performance.

The position of each box is meticulously checked before the gripper applies the handle.

The gripper is powered by a servomotor rather than a pneumatic cylinder to ensure precise control during the crucial phase of applying the adhesive tape to the box.

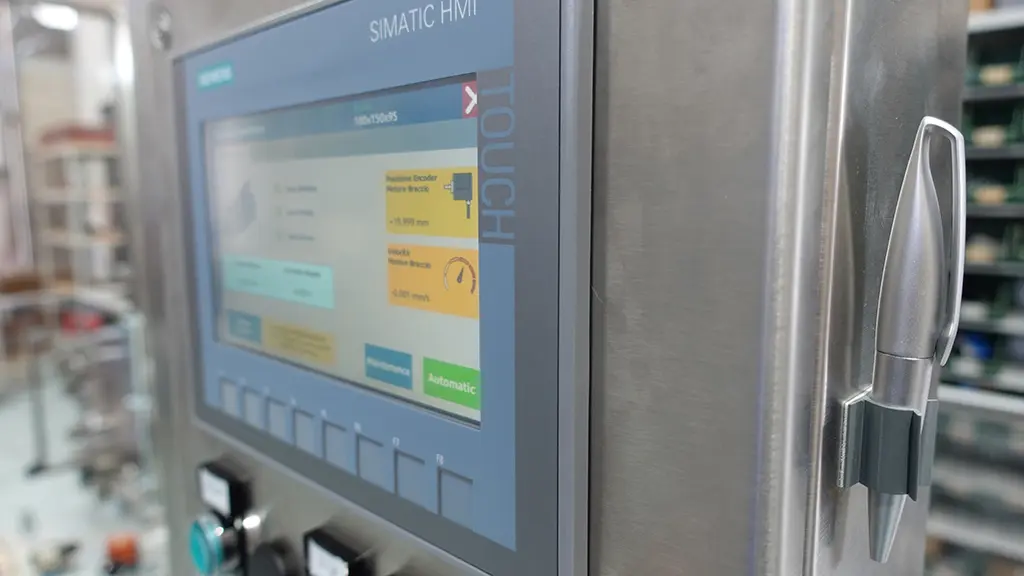

The control system is a Siemens S7-1200 PLC with related expansions and a 7" HMI touch display from the same manufacturer.

As with all our machines, a remote connection module is included for remote technical support.

We use excellent Omron Q2V inverters, communicating via Modbus, for conveyor belt control. The system allows easy box removal if necessary.