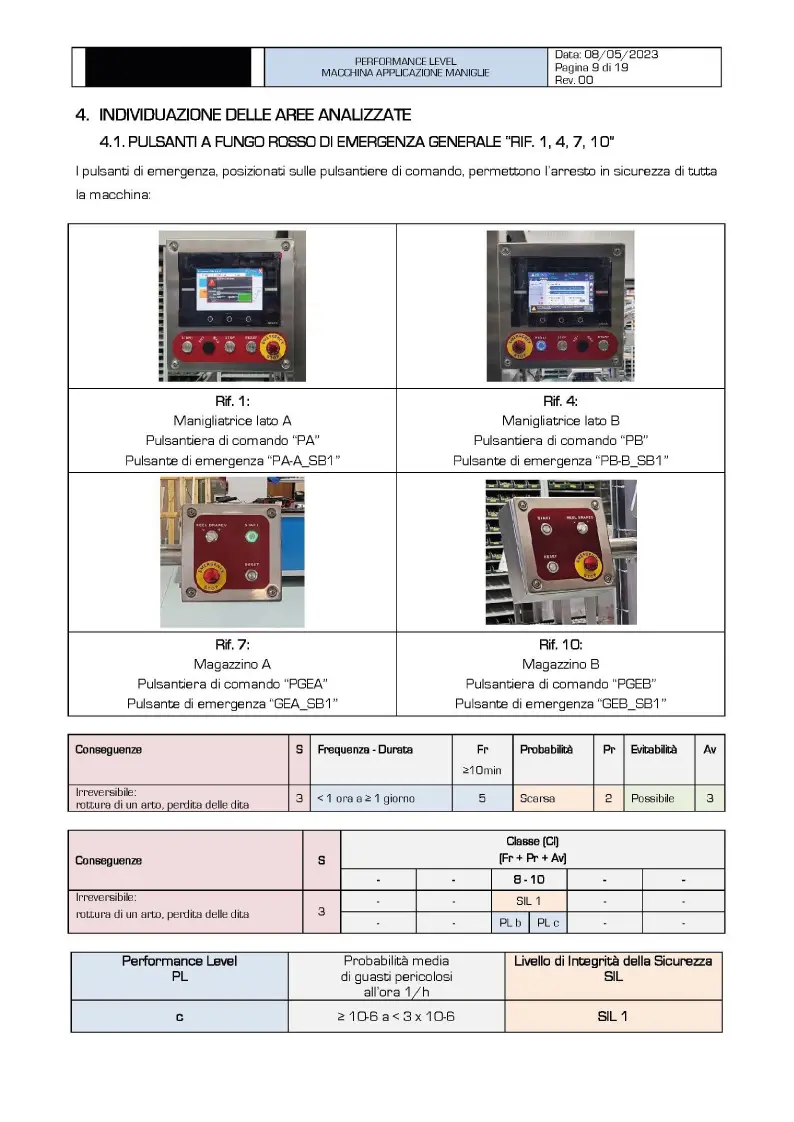

XHE Electronic Handle Applicator

The XHE Electronic carry handle applicator machine is one of the fastest and best performing machines on the market today. Unique and innovative features with patented application system.

Get Started

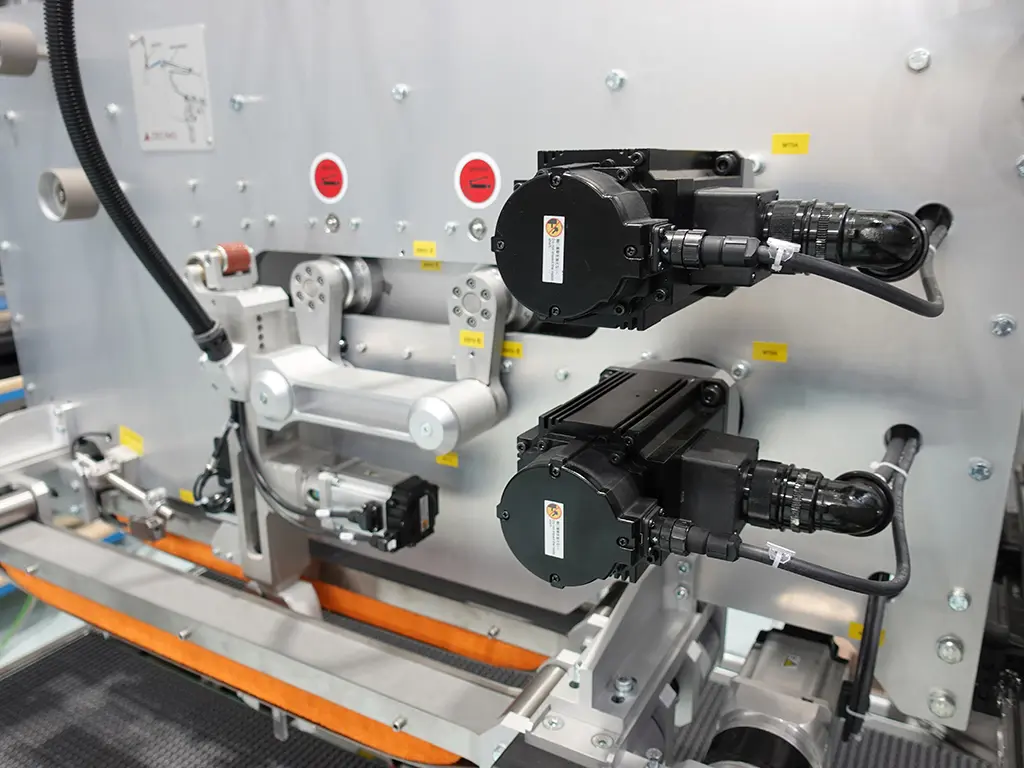

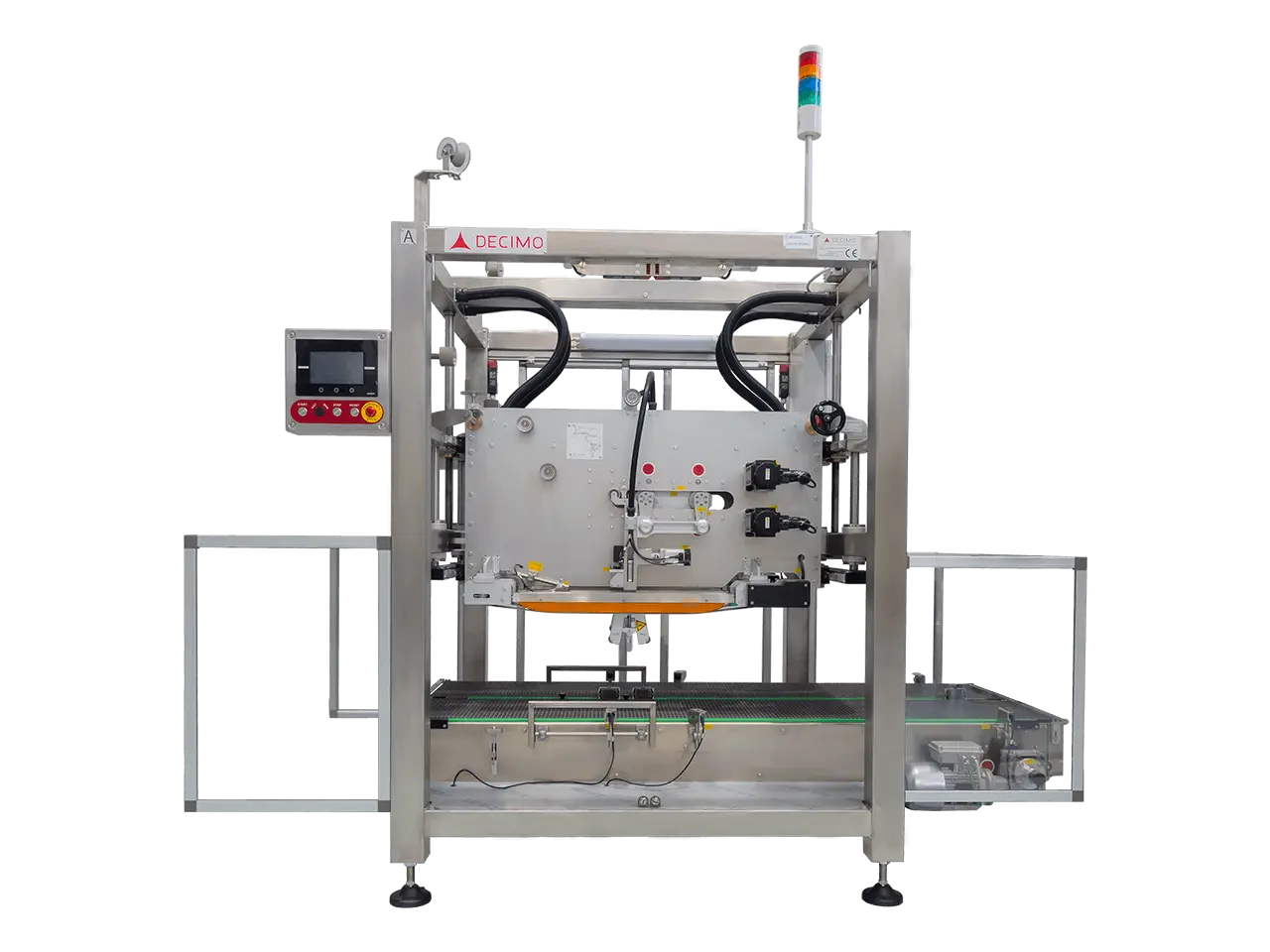

Patented application arm

The handle application arm of the XHE Handle Applicator is a patented mechanical device. The movement is harmonious and continuous for a long life of the components.

Get Started

XHE Handling System

Double lane handling system (54,000 bottles/hour) with XHE Electronic Handling Machine, pair of XHF-SCL adhesive tape and cardboard couplers, electrical cabinet.

Get Started

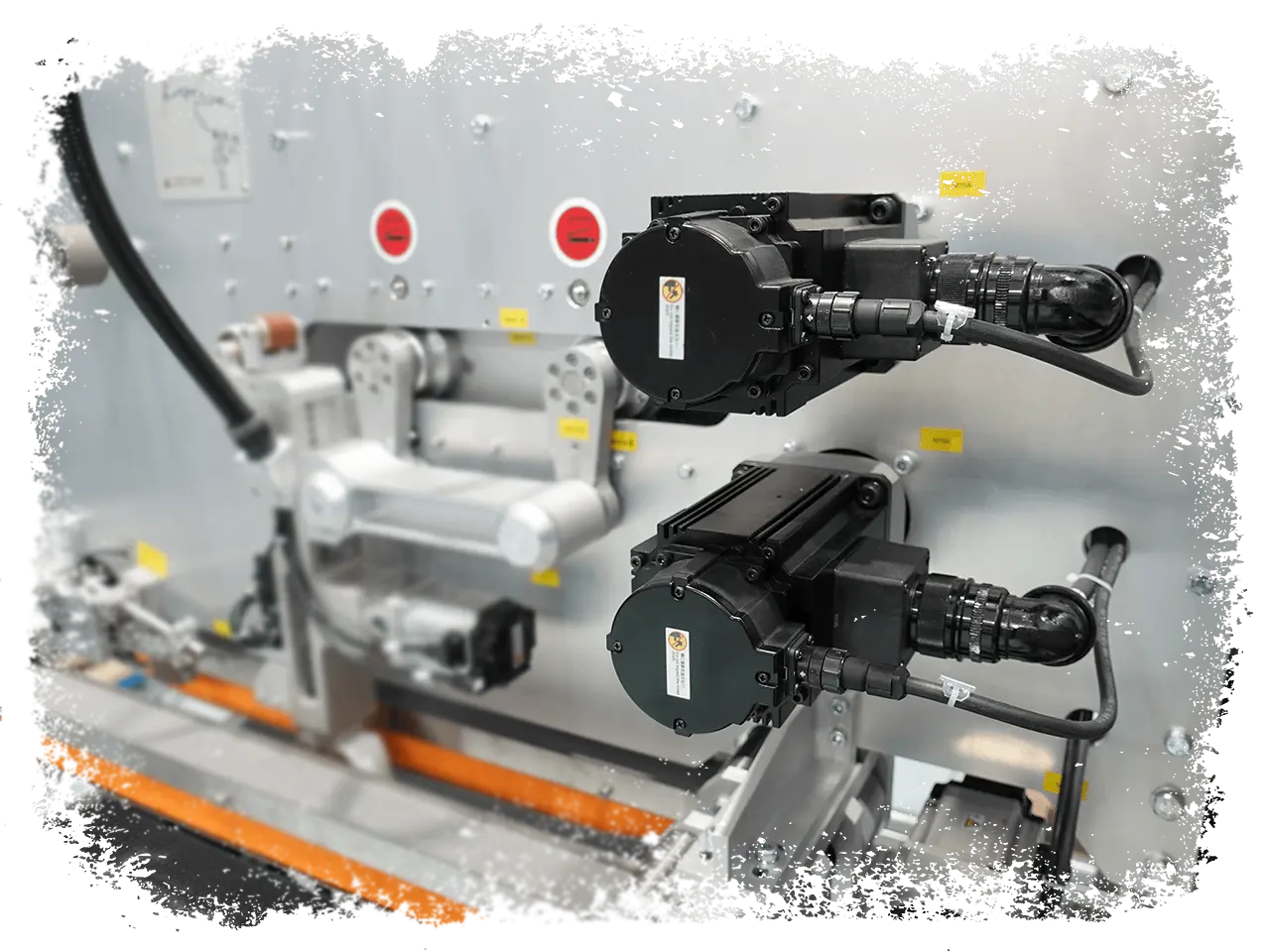

Does not require compressed air

The XHE Electronic Handle Applicator Machine is a totally synchronous machine with progressive start-up and speed changes. It does not require compressed air, there is no pneumatic component.

Get StartedAssemblies of the XHE Electronic Handle Applicator

In this section we want to describe the main assemblies of the machine. The section is interactive, click on the menu icons at the bottom to highlight the machine assemblies and the relevant descriptive sheet in the foreground.

System description

The electronic XHE Handle Applicator Machine represents the top of the selection of the handle applicator series for the application of adhesive handles. It is one of the best performing and fastest machines on the market with unique features:

- Reaches speeds of 100 packs/min on a single lane and 200 packs/min on a double lane applying the adhesive handle on 3x2 packs with 1.5 liter bottles with an optimal handle length. In case of a double lane machine the lanes do not depend on each other as if they were two completely separate machines.

This adds advantages such as not unbalancing the number of packages present on the lanes and also in some cases where double lane production switches to single lane for particular formats, one side of the machine remains stationary in the state of rest.

Often in license plate data of competitor machines it says that the speed is 130 packs/min and maybe even more, so attracting the attention of interested parties, but it is right to specify on which package format and above all how deep in relation to the shoulder of the bottle the handle is glued. For the same amount of adhesive tape, it is this length that makes the difference in the grip of the handle itself during transport. - The XHE model does not need compressed air, the handle applicator machine moves thanks exclusively to electric axes so as to have maximum reliability, repeatability, synchronism and precision at different speeds

- The our engineer's team developed a software able to manage the very high speed of the machine and specific algorithms for the perfectly way to applicate the handle in every specific algorithms to apply the handle perfectly in every transitory state of the machine, such as start stop phases, and during speed changes required by the line. In this way the machine adapts harmoniously with the other on the line.

Generally the handle applicator machine XHE is supplied with three different changes triggered both from the input (Shrink machine side) and from the output (Palletizer machine side) in order to avoid as much as possible numerous starts and stops of the machine, having enormous benefits on the life of the components and on the production efficiency. - One of the strong points of XHE handle applicator machine is the movement of the application arm (Patented) which is of the rotational-translational type, this innovative and functional conception of the movement is fundamental because it allows the two servomotors that move it to never reverse the direction of rotation.

The application arm never stopped during the cycles that improve the life’s of mechanical components, especially planetary gearbox and brushless motors. This is one of the first characteristics that are appreciated by the machine in function.

In confront of another machines presents on the market the XHE has a soft movement and progressive different to much others that is snappy and they seem to work “nervously”. We think only for one second what it can mean to stop an application arm in very shortly time when the speed is over 50-60 packs/min.

Product Guide

The XHE handle applicator machine comes with a system of product guide, equipped with mechanical transmission and adjustable means:

- Crank with mechanic position indicator

- Motor with mechanic position indicator whose target values are recorded in the recipe of the format to be worked, and can be visible on the display

- Motor with electronic position indicator. The regulation is possible by pressing the open or close buttons on the display, the dynamic value is shown on the display until the target value is reached

The guide can be configured according the characteristics of the line hosting the machine:

- Self-centering (unmovable centre to centre distance packs) handling happens thanks to single actuator, which at the same time tightens or widens the guides “A” and “B” of the tracks

- Unmovable insides guides and external adjustable, also in this case only one actuator works

- Unmovable insides guides and external adjustable separately (see animation) in this case has two actuators, the first works external guides and the second works with internal guides

The guides are very resistant and best quality, have a “C” core form in stainless steel, equipped with 4 crossed rows with large diameter wheels, so as to avoid the contact with unmovable support part causing damage.

The use of cheaper system is not reccomended on multiformat lines for the difficulty of the centering of the handle, often, by means of the lateral pushes is caused the deterioration of conveyor belts.

It is possible to request customizations to satisfy various needs, our technical office is at your disposal.

Brake conveyor

The function of brake conveyor is slow-down or speed-up the packs from the line. Its speed determines the speed of the machine in terms of packs/min.

In the project of the line we recommend a brake conveyor and an accumulation belt, to isolate the machine from the pushes of incoming packs. This two additional conveyor, can be supplied by Decimo as integrant part of the machine.

This system together with the sensors on the line do work armoniously the machine avoiding many stops and restarts. As already mentioned the spacer conveyor does not support pushes of every intensity, it also has the task of dosing the incoming packs, so receiving push varation could cause a wrong function.

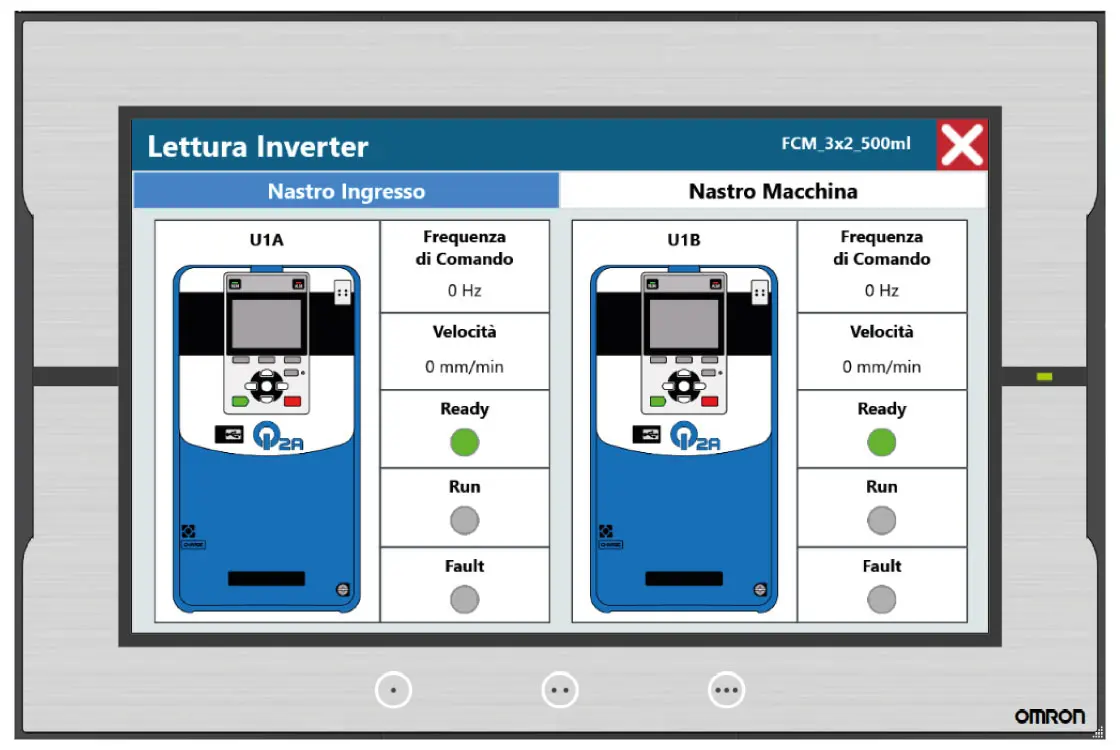

The brake conveyor is equipped with a asynchronous motor with encoder managed by inverter (see animation). this type of realization is important in the transitional phases, starting phase, stopping phase and change of speed because allows the acceleration and deceleration ramps to be precise and repeatable even with the interference of the pushes of the incoming packs.

Il nastro dosatore in oggetto non è in grado di sopportare spinte di ogni intensità a volte elevate a volte basse perchè (dipendente dal numero di pacchi in accumulo nelle retrovie). Mome detto, ha anche il compito di dosare i pacchi alla macchina, con notevoli variazione di spinta si potrebbe avere un funzionamento anomalo.

Il Nastro Freno è dotato di un motore asincrono con encoder gestito direttamente da un inverter con controllo ad anello chiuso (vedi animazione). Questo tipo di attuazione è importante soprattutto nei fasi transitorie, fase di arresto della macchina, di partenza e di cambio velocità perchè consente di avere delle rampe di accelerazione e di decelerazione controllate, precise e ripetibili anche con il disturbo dovuto alla variazione di spina dei pacchi provenienti da monte.

Spacer conveyor

Spacer conveyor belt is a fundamental part of XHE handle applicator machine, his operation is receive packs from BRAKE BELT and transport them to the handling phase with the right distance between the packages.

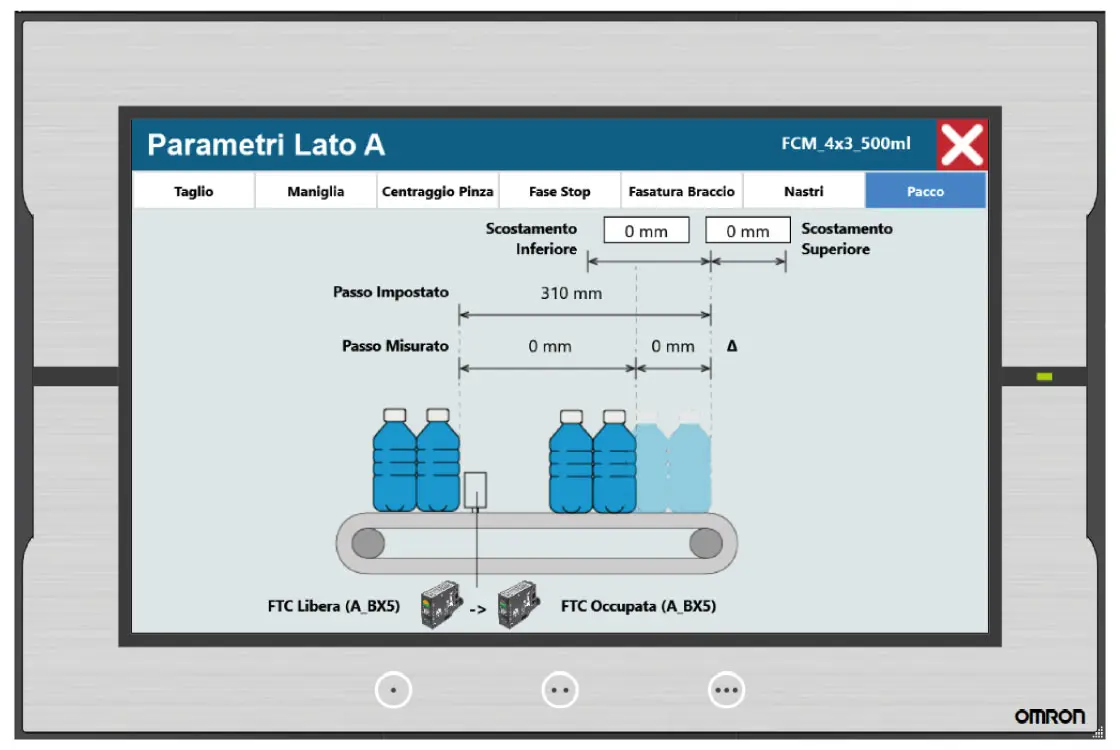

For the maximum accuracy of the pace, the spacer conveyor belt is equipped with a servomotor, on the conveyor belt there are sensors that measure the distance between a pack to the previous one, if the measure is out of the range, the programmed servomotor adapts the conveyor's speed for the right distance. This system is very reliable especially in the “Machine states” , as stops, arrests, speed change, because the machine fits perfectly into the line. To avoid wearing out the modular rubber chain the packages must slide at constant speed on the belt.

This belt is equipped with a series of stainless steel rollers on bearings made specifically to facilitate the passage of packages from the previous belt to the next as much as possible.

Handling conveyor

The handling conveyor is made with a modular chain with rubber inserts in order to keep the packages it transports as stable as possible. Like the brake tape is equipped with a asynchronous motor with encoder managed by inverter (see animation). The same type of control as the other tapes is used, so, the master encoder will rotate thanks to the movement of the tape measuring its exact position, connecting all conveyors belt harmoniously.

The master encoder is connected directly to the belt drive shaft.

Machine description

The structure of the machine is made in stainless steel with large section welded tubulars. Very resistant and the structure of the machine is not affected by the vibrations generated by the movement of the components. The structure is built only for the commissioned project.

The safety elements like doors or tunnels are made with aluminium frames with 5 mm thick transparent polycarbonate inside. The doors cannot be opened accidentally, this activates the operation of the door limit switches, blocking all movements of the machine, according to safety regulations.

The handle machine applicator with double lanes haves n.2 display (HMI), one for every side, This system does not require control panel arms, avoiding many downtime and production losses that it could cause. In case one breaks, another advantage is that you only need one panel to control the entire machine. The arm for the handling phase is stabilized by a belt device with sponge support, which works on the upper part of the package making handling easier. Usually this device does not need to be adjusted because it has a very varied range of forming both small and large ones.

One of the main innovations applied on the latest XHE handle applicator machine models is that the handle is always applied symmetrically in the center of the pack. Another great innovation of the latest XHE models is the slow and progressive start, stop and speed variations of the machine without compromising the centering of the handle in these phases. the engineers have developed a software able to applying the handle perfectly in long transitinal period. the arm is moved thanks to two servomotor like the blade for the cut of tape.

The XHE handle applicator machine

A series of images of XHE handle machine applicator: simple design, wiring taken care with maximum alert, mechanical parts easy to removable, first choice materials such as the use of aeronautical aluminium, very thick anodized aluminium head...

- All

- System

- Head

- HMI

- Details

- Wiring

XHE in action

Data sheet XHE-1

Below is the layout, some technical data and options relating to the xhe-1 electronic handle applicator (single lane). For every questions call technical office, we are happy to answer you.

Layout XHE-1

The layout of XHE-1 handle machine applicator (single lane) is available in DXF format, by clicking on it starts download that you can use for insert the our machine on layout of your lines. need to consider also electric cabinet that is outside of machine and handle forming unit and handle power unit.

If you interested of a complete layout, contact us and we sent you all of necessary. if you have a particular needs like narrow spaces and particular format for handling product, we able to:

- Carry out feasibility studies

- Propose a customized solutions

- Recommend the machine best suited to your needs both in functional and economic terms

Technical datas

Technical data relating to XHE-1 handle machine applicator (single lane).

The following data are related to the XHE-1 100 from 100 packs/min. If you are interested in data from the same machine series (XHE) but with lower maximum speed such as 70 packs/min or 40 packs/min contact us and we will provide you with all the necessary data.

- Machine model:

- XHE

- Maximum production:

- 36.000 bottles/hour

- Speed for lane:

- 100 packs/min

- Number of lanes:

- 1

- Electric power:

- 7,5 kWh

- Air pressure:

- Air not request in this model XHE-1-100 of 100 packs/min

- Air flow:

- Air not request in this model XHE-1-100 of 100 packs/min

- Power supply:

- 380-415 V

3PH-N-PE

50 Hz

Optional

Below the list of optional for XHE handle machine applicator. The optional preceded by this check are standard. The optional must be chosen when ordering the machine.

Usually when changing the product to be processed the application head must be repositioned. This operation can be do in different ways:

- Manual regulation, with crank and mechanic position indicator. When changing recipe , on the HMI panel in screen of regulation , we can find the new format values and apply them by the crank.

- Semi-automatic regulation, a motor that with buttons on the display and digital position indicator, can be regulated for the correct value that we need via the various buttons for adjusting the dimensions on the display.

Usually when changing the product to be processed the application head must be repositioned. This operation can be do in different ways:

- Manual regulation, with crank and mechanic position indicator. When changing recipe , on the HMI panel in screen of regulation , we can find the new format values and apply them by the crank.

- Semi-automatic regulation, a motor that with buttons on the display and digital position indicator, can be regulated for the correct value that we need via the various buttons for adjusting the dimensions on the display.

- Automatic regulation, with the same operation of Semi-automatic but we just press the only one “start adjustment “ button and the adjustment will be automatic.

Usually when changing the product to be processed the application head must be repositioned. This operation can be do in different ways:

- Semi-automatic regulation, a motor that with buttons on the display and digital position indicator, can be regulated for the correct value that we need via the various buttons for adjusting the dimensions on the display.

- Automatic regulation, with the same operation of Semi-automatic but we just press the only one “start adjustment“ button and the adjustment will be automatic.

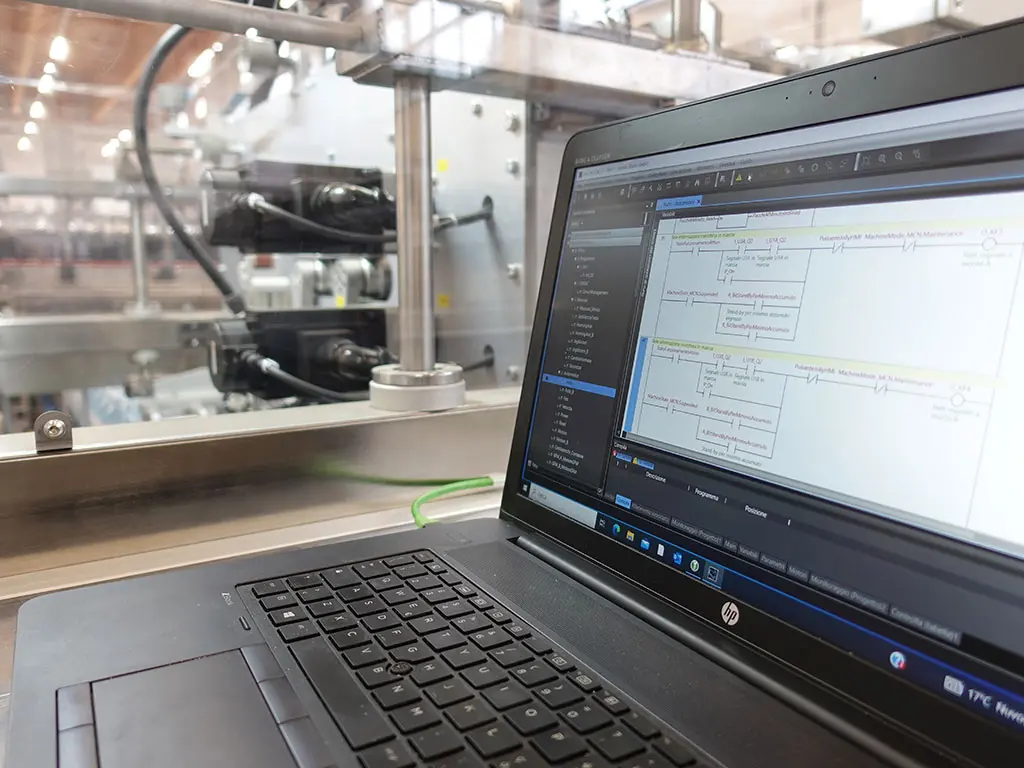

For remote maintenance interventions on PLC or HMI can use the remote assistance for reduce the intervention times and increasing the service quality’s.

Remote assistance contracts allow the purchase of a number of hours to be spent within a year, 360 days from the time of subscription, with remote interventions.

The types of devices available are:

- Router Lan to Lan

- Router Wi-Fi to Lan

- Router 4G to Lan

To allow technicians to view the machine remotely, a Poe type camera with Micro SD memory card is available as an option.

The camera is supplied in a container that contains a 10 m ethernet cable, this must be connected when needed. One end of the cable must be connected to the camera and the other end can be connected inside to the pushbutton panel box, to the appropriate connector, or inside the electrical cabinet to the dedicated Poe switch.

Through the free software made available by the manufacturer of the camera it is possible to view it and/or control the recording. The software is very simple to use and is also available as an "app" for smartphones and tablets.

- Poe type camera with micro SD type memory card

The device for formation handle arch is essential for realization of handle curvature for facilitate the entering of the hand for take the pack.

This device isn’t fundamental in all cases, but in only in 4x2 format because the tape it does not rest on the caps of the central rows as in the 3x2 format, thus failing to create the handle arch. There are two types depending on the speed of the machine:

- For speed of 40 packs/min for lane, need a alternating translational motion device

- For speed of 70 packs/min for lane, need a continuous rotary motion device

The cooling down of the electrical cabinets can happens in two system:

- Cooling down with fan

- Cooling down with electric air conditioner (advised)

The compact UPS for DIN rail avoid voltage drops and the power failure for PLC.

The 24 VDC power supply is backed up for a certain period of time in the possibility of a voltage drop or power failure. Compact, low weight and with long-lasting lithium-ion battery.

- UPS for PLC

The XHE Electronic Handle Applicator can be supplied with HMI display size:

- 7"

- 10"

Data sheet XHE-2

Below the layout, some technical data and XHE-2 (double lane) machine handle applicator optional’s. If need to other information contact us, our tecnical support office is happy to answear your questions.

Layout XHE-2

The layout of XHE-2 handle machine applicator (double lane) is available in DXF format, by clicking on it starts download that you can use for insert the our machine on layout of your lines.

Need to consider also electric cabinet that is outside of machine and handle forming unit and handle power unit (a unit for lane). If you interested of a complete layout, contact us and we sent you all of necessary. If you have a particular needs like narrow spaces and particular format for handling product, we able to:

- Carry out feasibility studies

- Propose a customized solutions

- Recommend the machine best suited to your needs both in functional and economic terms

Technical data

Technical data relating to XHE-2 handle machine applicator (double lane).

The following data are related to the XHE-100-2 from 100 packs/min. If you are interested in data from the same machine series (XHE) but with lower maximum speed such as 70 packs/min or 40 packs/min contact us and we will provide you with all the necessary data.

- Machine model:

- XHE

- Maximum production:

- 72.000 bottles/hour

- Speed for lane:

- 100 packs/min

- Number of lanes:

- 2

- Electric power:

- 12,5 kWh

- Air pressure:

- Air not request in this model XHE-2-100 of 100 packs/min

- Air flow:

- Air not request in this model XHE-2-100 of 100 packs/min

- Power supply:

- 380-415 V

3PH-N-PE

50 Hz

Optional

Below the list of optional for XHE handle machine applicator. The optional preceded by this check are standard. The optional must be chosen when ordering the machine.

Usually when changing the product to be processed the application head must be repositioned. This operation can be do in different ways:

- Manual regulation, with crank and mechanic position indicator. When changing recipe , on the HMI panel in screen of regulation , we can find the new format values and apply them by the crank.

- Semi-automatic regulation, a motor that with buttons on the display and digital position indicator, can be regulated for the correct value that we need via the various buttons for adjusting the dimensions on the display.

Usually when changing the product to be processed the application head must be repositioned. This operation can be do in different ways:

- Manual regulation, with crank and mechanic position indicator. When changing recipe , on the HMI panel in screen of regulation , we can find the new format values and apply them by the crank.

- Semi-automatic regulation, a motor that with buttons on the display and digital position indicator, can be regulated for the correct value that we need via the various buttons for adjusting the dimensions on the display.

- Automatic regulation, with the same operation of Semi-automatic but we just press the only one “start adjustment “ button and the adjustment will be automatic.

Usually when changing the product to be processed the application head must be repositioned. This operation can be do in different ways:

- Semi-automatic regulation, a motor that with buttons on the display and digital position indicator, can be regulated for the correct value that we need via the various buttons for adjusting the dimensions on the display.

- Automatic regulation, with the same operation of Semi-automatic but we just press the only one “start adjustment“ button and the adjustment will be automatic.

For remote maintenance interventions on PLC or HMI can use the remote assistance for reduce the intervention times and increasing the service quality’s.

Remote assistance contracts allow the purchase of a number of hours to be spent within a year, 360 days from the time of subscription, with remote interventions.

The types of devices available are:

- Router Lan to Lan

- Router Wi-Fi to Lan

- Router 4G to Lan

To allow technicians to view the machine remotely, a Poe type camera with Micro SD memory card is available as an option.

The camera is supplied in a container that contains a 10 m ethernet cable, this must be connected when needed. One end of the cable must be connected to the camera and the other end can be connected inside to the pushbutton panel box, to the appropriate connector, or inside the electrical cabinet to the dedicated Poe switch.

Through the free software made available by the manufacturer of the camera it is possible to view it and/or control the recording. The software is very simple to use and is also available as an "app" for smartphones and tablets.

- Poe type camera with micro SD type memory card

The device for formation handle arch is essential for realization of handle curvature for facilitate the entering of the hand for take the pack.

This device isn’t fundamental in all cases, but in only in 4x2 format because the tape it does not rest on the caps of the central rows as in the 3x2 format, thus failing to create the handle arch. There are two types depending on the speed of the machine:

- For speed of 40 packs/min for lane, need a alternating translational motion device

- For speed of 70 packs/min for lane, need a continuous rotary motion device

The cooling down of the electrical cabinets can happens in two system:

- Cooling down with fan

- Cooling down with electric air conditioner (advised)

The compact UPS for DIN rail avoid voltage drops and the power failure for PLC.

The 24 VDC power supply is backed up for a certain period of time in the possibility of a voltage drop or power failure. Compact, low weight and with long-lasting lithium-ion battery.

- UPS for PLC

The XHE Electronic Handle Applicator can be supplied with HMI display size:

- 7"

- 10"

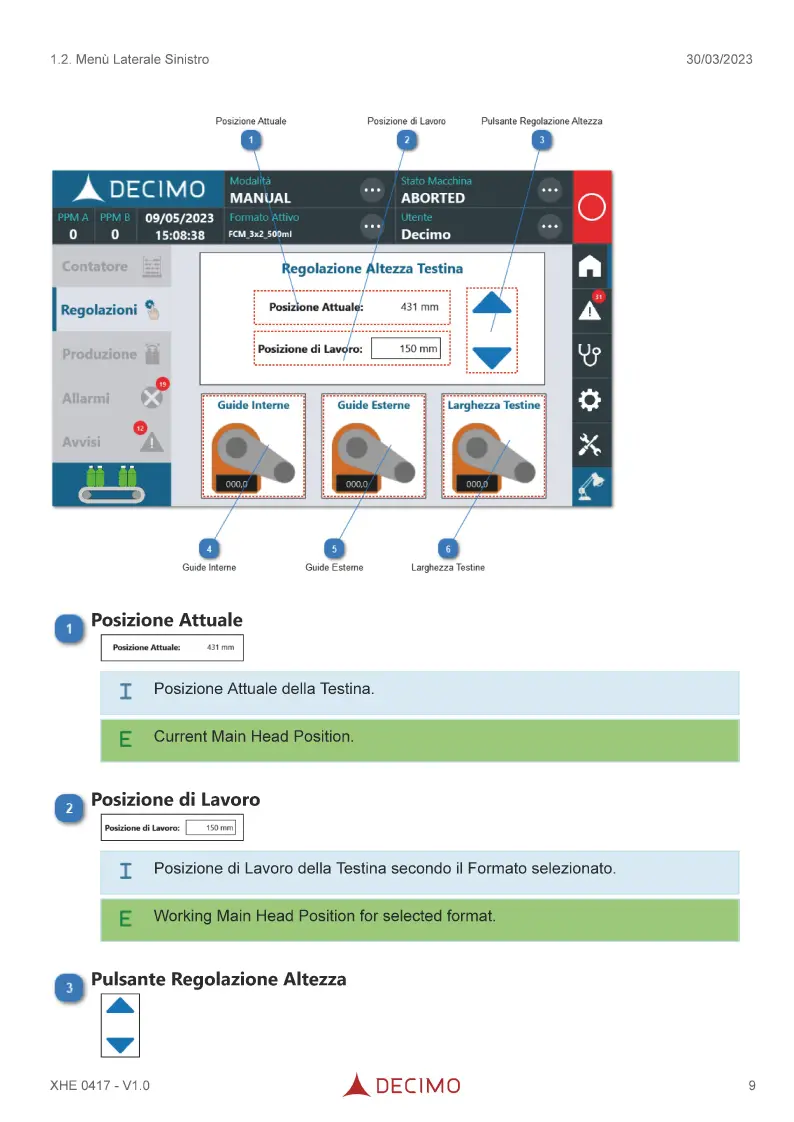

Production change

The XHE handle machine applicator is equipped of fast change production divided in "tre" system to regulate:

- side guide for product in entrance

- Widht of the handle application heads

- Height of the handle application heads

The regulation can be of this type:

- Manual

- Semiautomatic

- Automatic

For manual adjustment there is a crank connected with a position indicator. On the display can pick and watch the correct value for your format to work with, and reach by crank.

In semiautomatic adjustment there isn’t a crank but a motors that move thanks to the button raise/lower or widen/tighten on the HMI panel.

In automatic adjustment is only need the pick of the correct format that you want work with, all the rest of movements are automatic for all formats.

side guide for product

The guides can be configured based on for the needed line characteristics:

- Self-centering (fixed wheelbase parcels), in this case the movementation happens by only one actuator that provvise to widen or tighten at the same time the guides of lane “A” and lane “B”

- Internal set guides and adjustable external , also in this case the regulation happens by only one actuator

- Internal and external guides adjustable separately (see animation), but in this case we need of two actuators, the first will work only for external guides and the second one for internal

Application head width

The widht of head in the double lane line’s is fast adjustable any is the choose configuration. The design of the machine allows for very small center distances of the application arms (see animation). The adjustment can be of two types

- Simmetric, in this case the movement happens by single actuator which simoultaneously widens or tightens the head to the same extent

- Separate, in this case the adjustable happens by a double actuator, the first is responsible of “A”, the second of “B”

Application head height

The adjustable of height of head in case of single lane or double lane, dipend by means a controlled gearmotor through buttons present in the specific page on the display.

The heads are equipped with a position sensors that provvise to indicate the value reach simoultaneasly and a sensors limit switch on the extreame positions.

This system is present in the basic configuration of the machine already.

Each recipe has his format value next to actual dinamic value sent to position sensor, this to avoid sticking tables aroud the machine.

Human-Machine Interface

For Decimo one of the most important components is a HMI (Human-Machine Interface), is used for use and control the machine by the operators and maintenance technicians, have a team that work only for this, starting to the software and ending with the user manual (HMI User Manual).

The double lane’s handle machine applicator has a n. 2 HMI display, once for side. This avoids having the push-buttons panel holder arm that moves around the machines taking up a lot of usable space.

In the standard version of the XHE handle applicator the display is 7" large, it is possible to have it 10" or more.

The interface is well organized with many images to clearly understand the use of each individual page. For this software our team has developed a user manual to be as clear as possible. The user manual is available in many formats: PDF, CHM or HTML5.

The HTML5 format is available in portal for assistance dedicated to our customers, can be accessed by logging in, and also have it available on your smartphone. In this way with this format is possible to have the manual always updated.

The software can be update, by editing or adding pages (sometimes can be do by teleassistance).

The user manual contains everything relating to the machine explained step-by-step, for example changing recipe’s and much more.

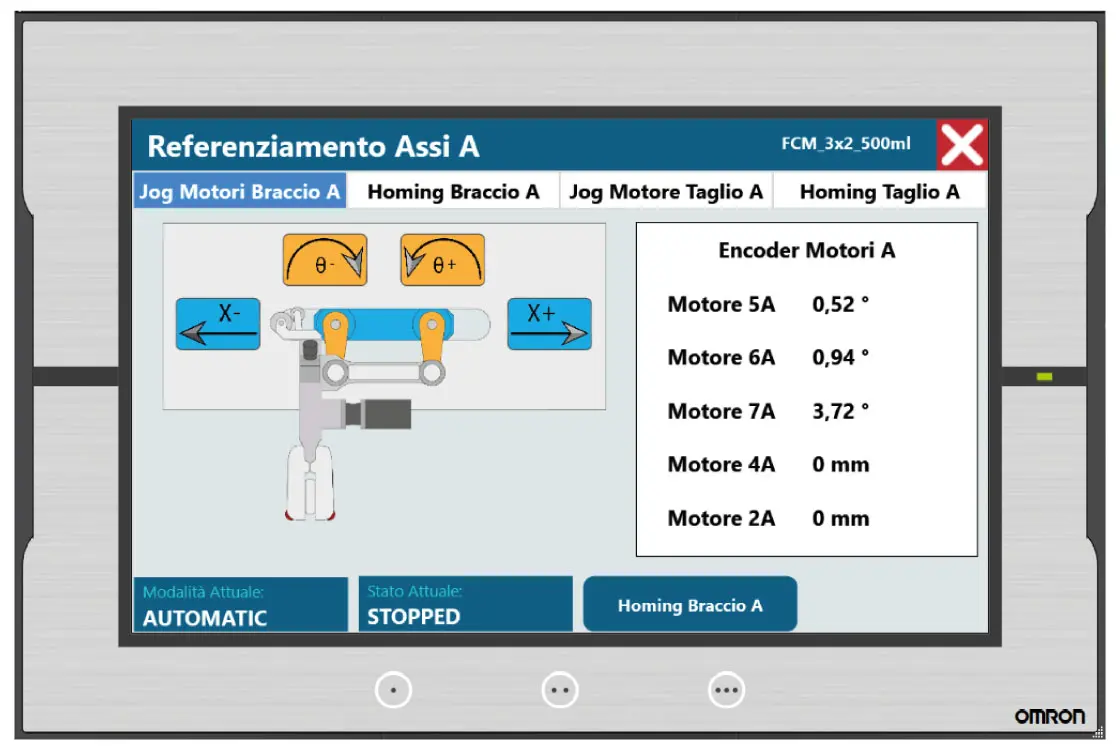

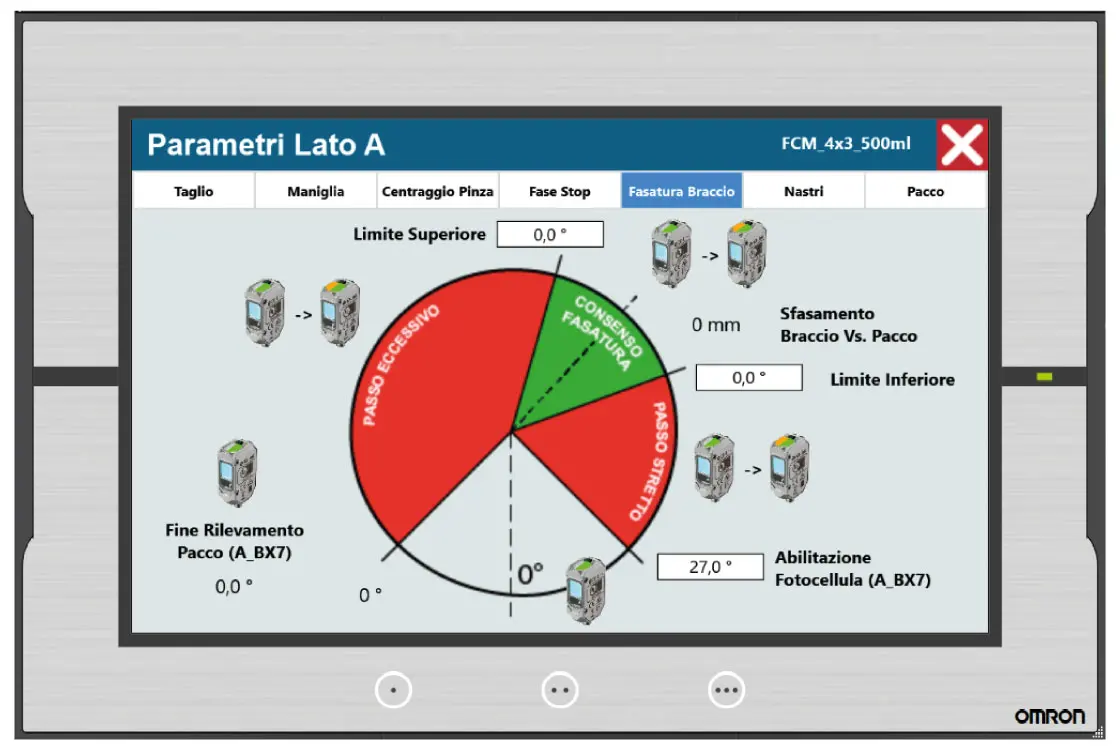

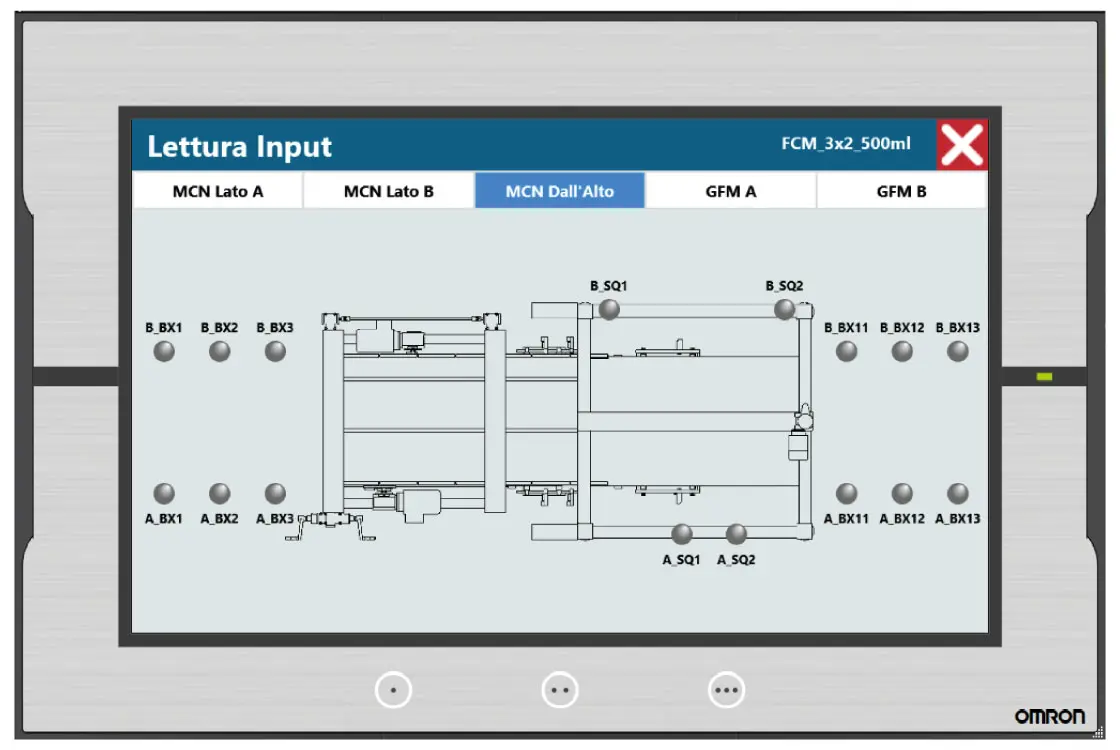

Below are some pages as an example.

Home Page

The home page contains fast connections with most common operation and various value of first interesting

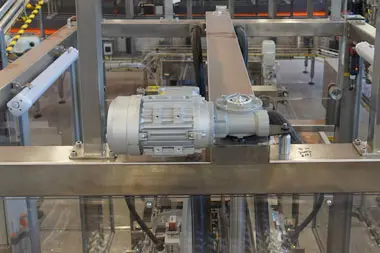

Machine State

The machines are programmed according to the standard of PackML developed by OMAC (The Organization for Machine Automation and Control)

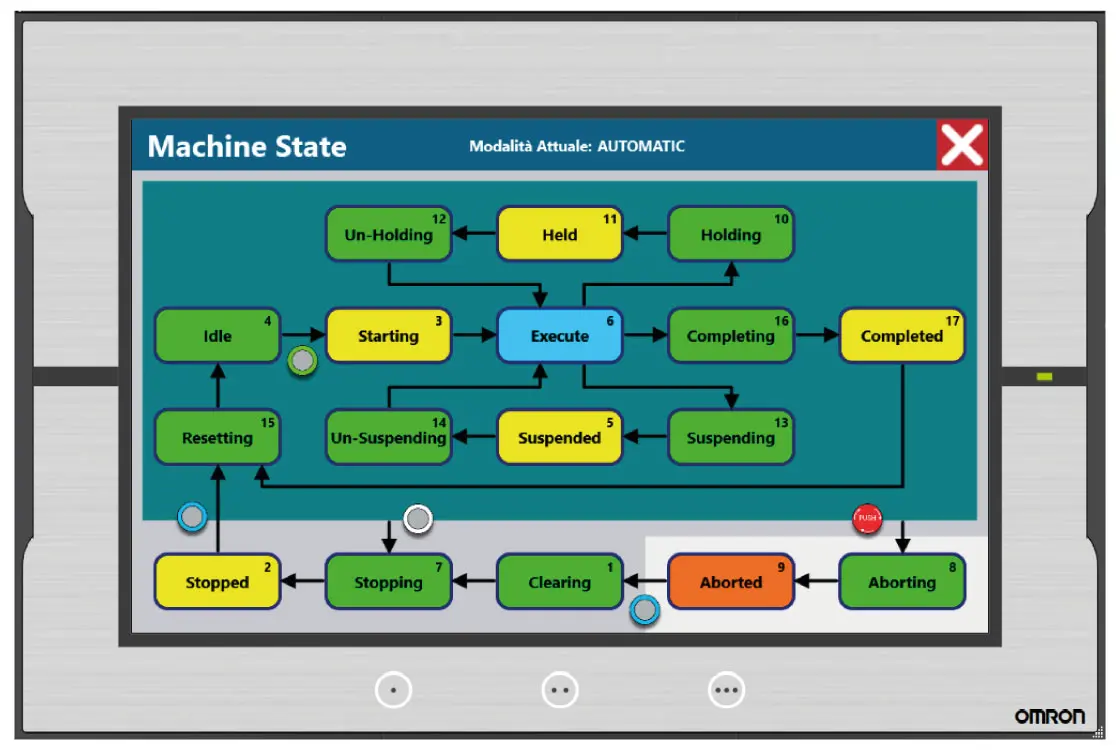

Recipe book

On this page there is an archive of formats to be handled and not. On panel there is a database that saved all the formats, if they are saved incorrectly, you can modify or delete them.

Arm jog

This page is dedicated to the value of movement of the arm, with clear and intuitive graphics.

Cycle phases

Diagram with all phases of machine state classified under different name.The values are expressed in degrees.

Inverter states’s

In this page can see the all the values relating the inverter, for example frequency or speed of conveyor belt. (Vector inverter with closed loop control)

Pack parameters

It is a setting page , with an intuitive graphics, while the setting you can see the sensor specifically that we are setting.

Technical documentation

The technical documentation contains information of project, manufacturing and the operation of a product, included all the information needed to demonstrate that the product in compliance with the necessary requirements.

HMI user manual(Human-Machine Interfaces)

The user manual is a fundamental part for control the machine, it was developed in detail and carefully. Thanks to custmers feedbacks’s we can check and update the manual. Is available online in various formats for easlier to search him.

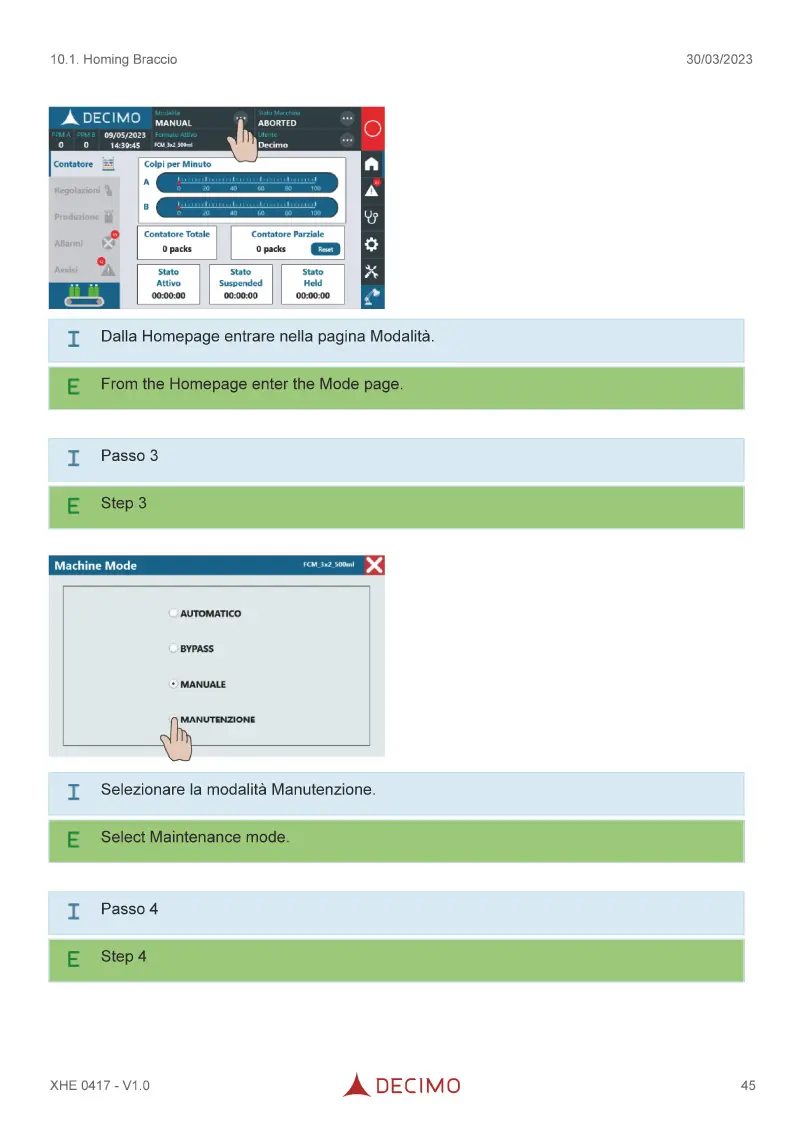

Smart Pages

The interface is a smart type, very easy to intuit and fast, many links, and graphics realized with carefull for make them easy to understand at manual operator. Each command have an icon where it is rappresented the action of the command.

Procedure

IMPORTANT!!! The manual contains different operative procedure, for example, most common operation: Change recipe, resetting of the handling arm, ecc…. This procedure is step-by-step and there is an handle-shaped indicatorm that tell which buttons to press in sequence.

Problem solving

In addiction to managing the life of the components, a warning message will be reported when a component reach the life limit’s declared by the manufacturer, for example a solenoid valve, contains a series of problems and indicate the way to solve them.

The file of user manual

The user manual is available in different formats:

HTML5 format, this is the most important beacuse is available online, by loggin in customer’s portal with username and password, and is viewable too with the smartphone.

Use and maintenance manual

Often the quality about the manual of how it is written is underestimated, is not just a legal obligation, if for example, a machine is shipped abroad , the manual must be written and translated very carefully, or the reader risks not understanding what is written. The first regulatory references on the employer's responsibility in terms of safety arrive with the European Directive 89/391/EEC, approved in 1989, and implemented in Italy with Legislative Decree 626/1994 which establishes the obligations and duties regarding workplace safety for both employers and workers. 2006 is the year in which the European Community renewed the Machinery Directive: in this directive it was definitively clarified what an instruction manual should contain, with the specific list of information to be provided to its user

Clear information

The images are worked very carefull, in order to make the information as simple and clear as possible.

Ease of understanding vocabulary

The concepts are expressed through simple sentences, understanding the manual is accessible to everyone, especially regarding the safety regulations, regardless of the cultural level of the reader.

Illustration of the technical documentation

To make it easier for the reader to understand, the manual is full of illustrations created with specific software.

Language translation

The manual translation is commissioned to an external company specialized in translations of technical manuals.

Review and update of the use manual

The manual can be updated and reviewed for various reasons, for example if a part in the machine is replaced. Also for this reason, the constantly updated online format is available

Pay attention to the rules

Decimo has external professional collaborators who constantly review the continuously updated rules.

Spare parts manual

The after-sales service will fully satisfy the customer's needs after the sale. starting from telephone assistance up to spare parts. The service has the only one objects that is provide to customers the best quality of the after-sales service.

Project catalogue

The spare parts catalogue is realized specifically for each project. (We don’t supply general catalogue, which do not represent the actual components used).

Illustrations

The all catalogue illustrations are realized joining the various parts of the exploded cad. (we do not use incomprehensible photos to avoid confusion when ordering)

Codes

each component in each drawing is exploded and has a numerical classification, which we find in the table where they are represented: component number, purchase code, description and quantity

Availability review and periodic updating of the manual

The spare parts catalogue is available online for customers, to order the spare parts is recommended the last one version of the catalogue. (Please Remember that the catalogue is in costantly update).

Online spare parts catalogue

Soon as possible this catalague will be available online foe everyone, and will possible to order in interactive ways with the net price according with customer.

Wiring diagrams and Plant Technical File

The wiriring diagrams respect the actual normative and be realized with professional software. Beyond the wiring diagrams contains all a series of attachments like technical data sheets and manuals of the relevant components.

Multilingual

The diagrams in digital form, usually in PDF are multilingual. Just select the language in the menù.

Electrical cabinet layout's

The document contains 2d and 3d electrical cabinet layout’s with realistic rappresentation of components.

Reports

The document contains various report as: Cable list, references, ecc… Also materials list the most important report, it is a summary of all the materials used.

Images

At the side of every symbol there is an image to help the operator understand.

Tire diagrams

The tire diagrams complies with current regulation and are created with professional software.

Diagram in language

Tire diagrams are supplied with the language chosen about the customer.

Material report

The document is a list with all used components in the project.

Detailed rapresentation

In Tire diagram are present all sections of the pipes, color of the pipes, type of connection, air-distributor and many details too.

Technical file

For a safety product , under the law, there is must be all documentation that approve the compliance of this product, in all his production rute. The manufacturers are obliged to provide the competent authorities with all necessary documentation relating to safety regulations. This documents allow to manufacturers to dimostrate that his project are designed and realized follows all the normative standard, without this documentation is impossible to prove the standard conformity of a product.

Declaration of conformity

The declaration of conformity (Di.Co.) is an obbligatory document , released for the companies by the Chamber of Commerce. This document prove that this product can be able follows all the standard normative, so is able to the sell.

CE marking

More products need the CE Marking before be able to selling in the UE. The CE Marking ceritifies that the product has been evaluted by the manufacturer and respect the required requirements by UE in safety, health and environmental protection.

Certificates, tests and various verification reports on the product

All tests and verification reports are reported in the technical file.

Performance Level

The perfomance level is the valutation about the level of performance in safety function under certain knows conditions.

The Performance Level

The safety function is a function about the machine or a machine devices that have the work of protect a part in case of broken, that increase the risk. Is a transmitted and managed signal about PLC (better if dedicated) to managed the safety. Is necessary to eliminate/lower the risk more as possible the risk of possible dangerous situation for the operator. The performance level is classified with five performance level, identified with letters in ascending order from A to E as the risk level increases: a “E” PL is a better level of safety, “A” instead "A" of a very low level.

Sysmac platform

Powerful and robust automation platform, equipped with a new controller (NJ) which complete movements, logics, safety, networking and visual inspection, a new software (Sysmac Studio) which includes configuration, programming , simulation, monitoring and an extremely fast machine network (EtherCAT) for controlling motion, vision, sensors and actuators.

- Once control for the entire machine or production cell.

- The fastest network on the market, with upgrade’s time of 100 μs e jitter less than 1 μs.

- Only one software about control and configure entire machine with only one connection offer the appropriate power and efficency for do development operation and realization unprecedented.